WHAT WE DO

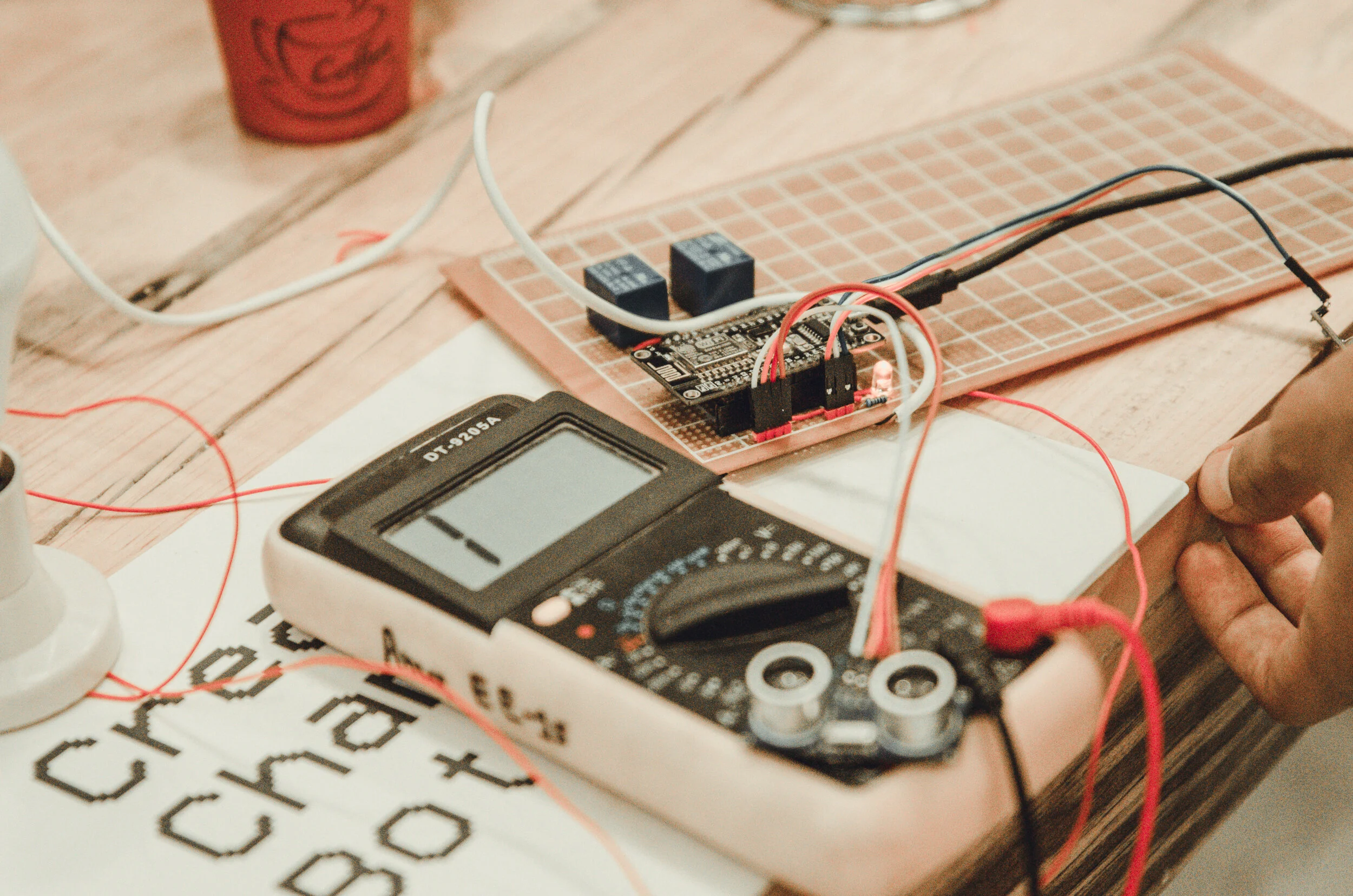

Eye-Def USA was built to streamline the product development process and provide full transparency. We have the tools and experience necessary to take our projects from inception to reality.

When it comes to quality and assurance, we haven’t left any room for uncertainty. We welcome our clients to be as hands on as they would like. From choosing materials samples from our extensive libraries to providing sustainable shipping options, we are with you all the way.